Software

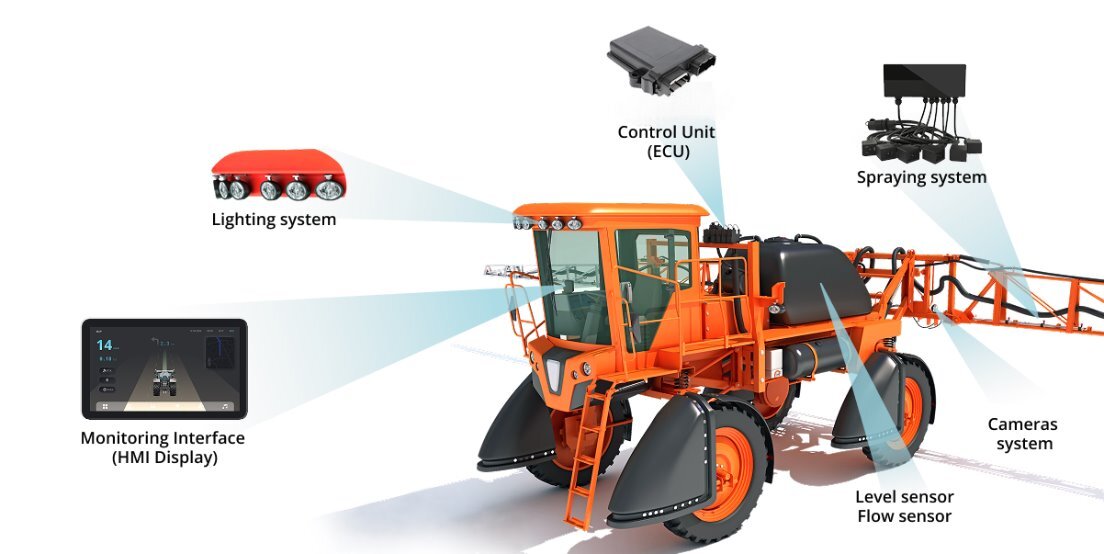

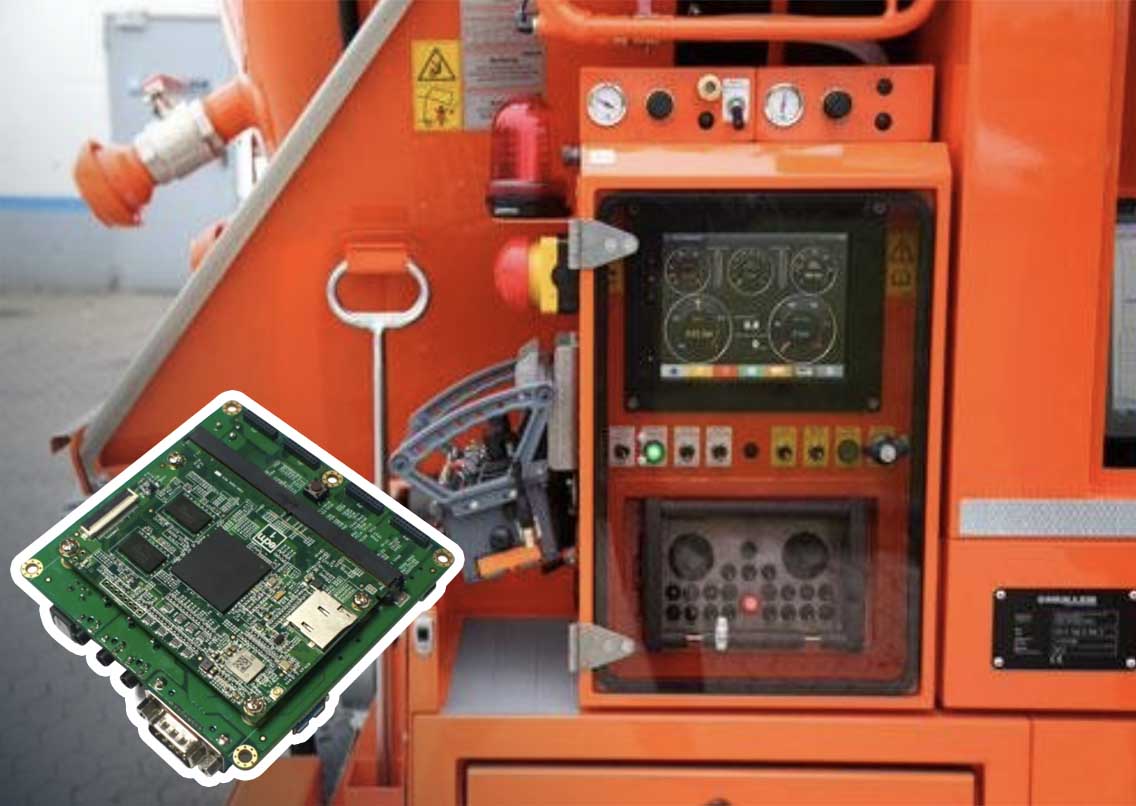

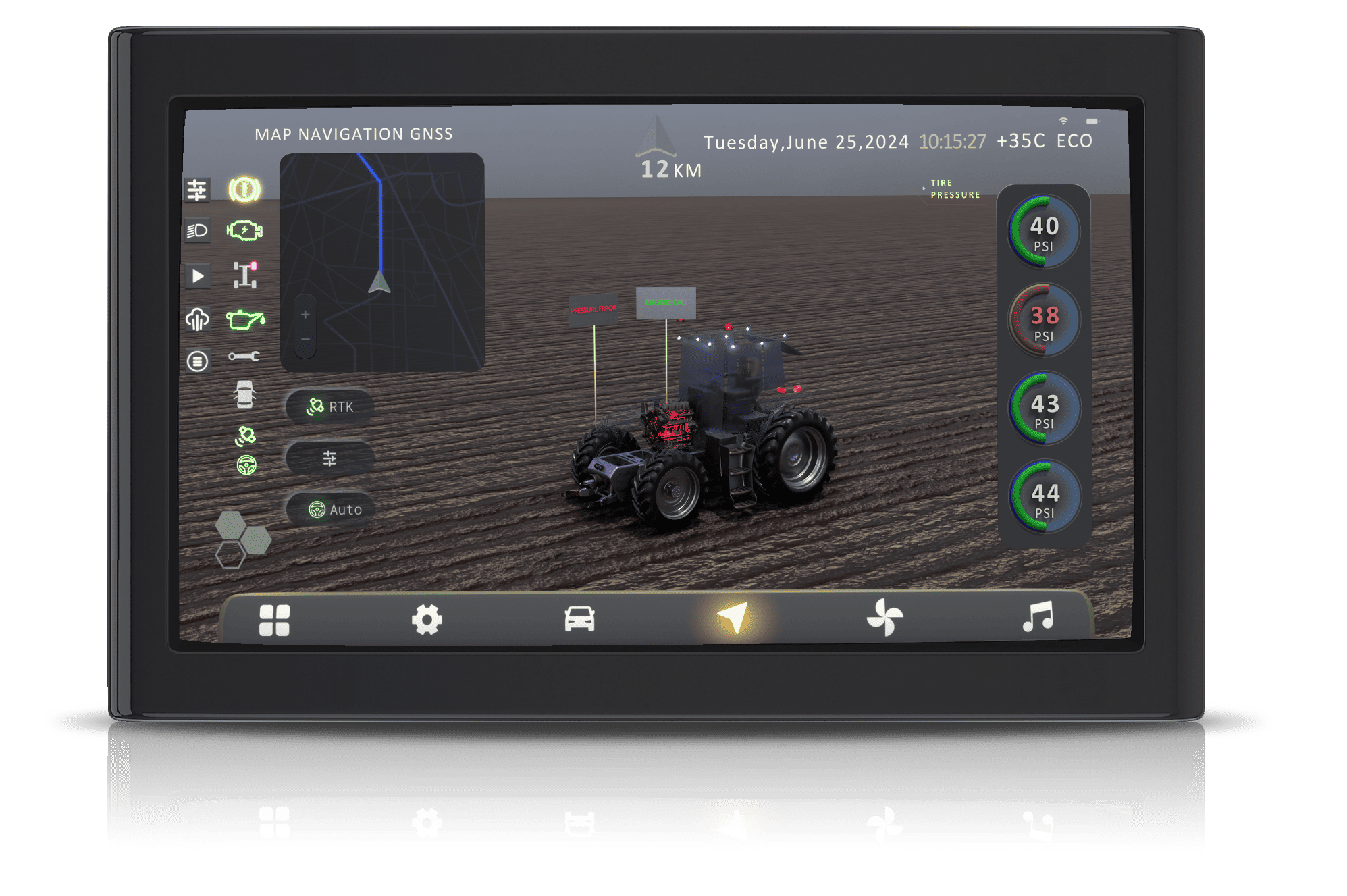

Our engineers develop low-level and high-level agricultural machinery software to provide seamless functionality and top-notch user experience.

We create firmware and control algorithms that enhance precision and interaction between hardware components.

Additionally, our designs for agricultural machinery include integrating robust data analytics tools to ensure real-time insights.