Custom

Enclosures

Custom Enclosure Design for Electronic Devices

- 20 years of experience delivering custom enclosures and mechanical engineering according to the design for manufacturing (DFM) approach.

- A proven track record of successful enclosure design projects, providing both protection and aesthetics.

- End-to-end design services: from enclosure style development to mechanical engineering and manufacturability analysis, we handle it all with our IT infrastructure.

Pavel Moroshek, Head of Embedded Engineering Unit at Promwad

Enhance Your Time-to-Market with Promwad

Finding a design partner is challenging

Stay ahead of the competition with our team

Enclosure Development Project Stages

At Promwad, we carry out the entire process of enclosure design, prototyping, and manufacturing.

1. Requirements

Preliminary research, market survey, pricing factors definition, production requirements implementation

2. Materials

Examination of the customer’s project based on the selected materials

3. Sketches

The first sketches and 2D/3D photorealistic images in a variety of colour and texture solutions

4. 3D modelling

For a more detailed elaboration of the future device, our designers develop a 3D model

5. DFM

Еnclosure prototyping and preparation for mass production in Europe or Asia

6. Production launch

We organise production in the optimal locations worldwide and offer consultations

Result

You get a reliable end device with the required protection against solids, dust, falls, and water with unlimited immersion time to a certain depth.

With our enclosure design services, you control the entire process, from creating the concept to the final ready-to-use device.

Results of Our Enclosure Design Services

Design documentation

A project file with enclosure design details: costs, components, technologies, and specifications.

Drawings for enclosure production

Detailed blueprints with dimensions, materials, and assembly instructions necessary for manufacturers.

Product

samples

An enclosure prototype for evaluating quality, functionality, and performance before mass production begins.

Why Promwad

Style

We develop custom electronic enclosures following client needs and the latest market trends in terms of both style & development.

Reliability

Our custom enclosure solutions meet the specified requirements for tightness, flexibility, and strength, all in accordance with IP standards.

Professionalism

We guarantee the perfect project outcomes based on our vast experience in industrial design, engineering, and production launch.

Our Industrial Design Engineering Tasks

IP rating / Sealing

Protection against drops, splashes, jets, flooding, dust

Vandal-resistant enclosures

Shock and fall protection

Two-component (2K) materials

Protection against corrosion

Components cooling

Thermal simulations to implement ventilation requirements

Injection moulding simulation

Better moulded parts without defects

Shock and drop simulation

Explore Our Completed Projects

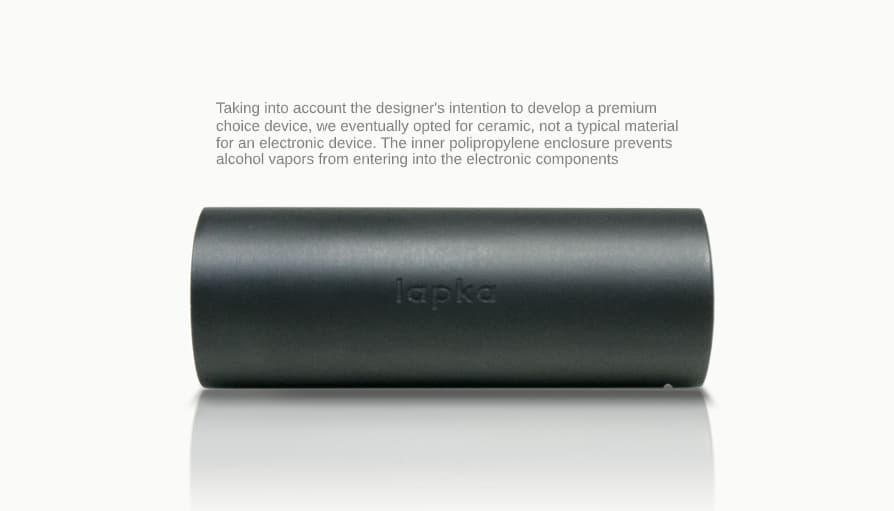

We have developed a custom enclosure, taking over the mechanical design and production start-up as well. We provided a high degree of protection against dust and moisture according to the IP67 standard. The robust rubberised device withstands falling from a height of 1.5 m on a hard surface. We also implemented a hermetically sealed sensor connector inside the device and made it easy to assemble and maintain.

What Our Clients Say

"At Kino-mo, we have developed the 3D Holo-Display, an innovative product which makes it possible to project 3-D images in the air. We turned to Promwad with the task of manufacturing new samples"

"Today, our IPTV STB is available at the market and competes on an equal footing with products by the world's leading manufacturers, such as Aminet and Motorola."

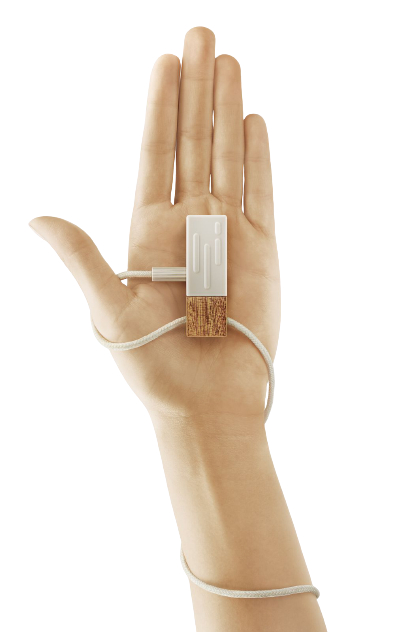

Materials for Electronics Enclosures

Thanks to our excellent supply channels, we are ready to work with any materials for your electronic case design:

- Plastics: ABS, ABS+PC, EK, PC, PE, PVC, PMMA, polyamide plastics, and others.

- Woods: different wood species, including composite combinations, such as wood + plastic.

- Metals: production of device enclosure parts from stainless steel, aluminium, and aluminium-magnesium alloys, using various technologies (stamping, moulding, milling, extrusion moulding).

At the customer's request, we can also utilise other materials in industrial processes, including rubber, ceramics, glass, and more.

Sometimes, materials chosen for mass production (e.g., plastics) may not be suitable for the prototyping stage. In such cases, we use an analogue that closely matches the original material's characteristics.

More of Our Case Studies in Custom Enclosure Development

Drop us a line about your custom enclosure design & manufacturing project and get a quote!

We will contact you today or next business day. All submitted information will be kept confidential.