Industrial

Design

Quick-Turned Industrial Design Services for Electronics

- End-to-end design services: from enclosure style development to mechanical engineering and manufacturability analysis, we handle it all with our IT infrastructure.

- Explore our successful projects that balance quality with competitive pricing and eco-friendly design.

- 20 years of experience delivering production-ready designs for clients worldwide, whether it's for mass production, low-volume or high-value manufacturing.

Pavel Moroshek, Head of Embedded Engineering Unit at Promwad

From Concept to Production: Modern Design for Our Clients

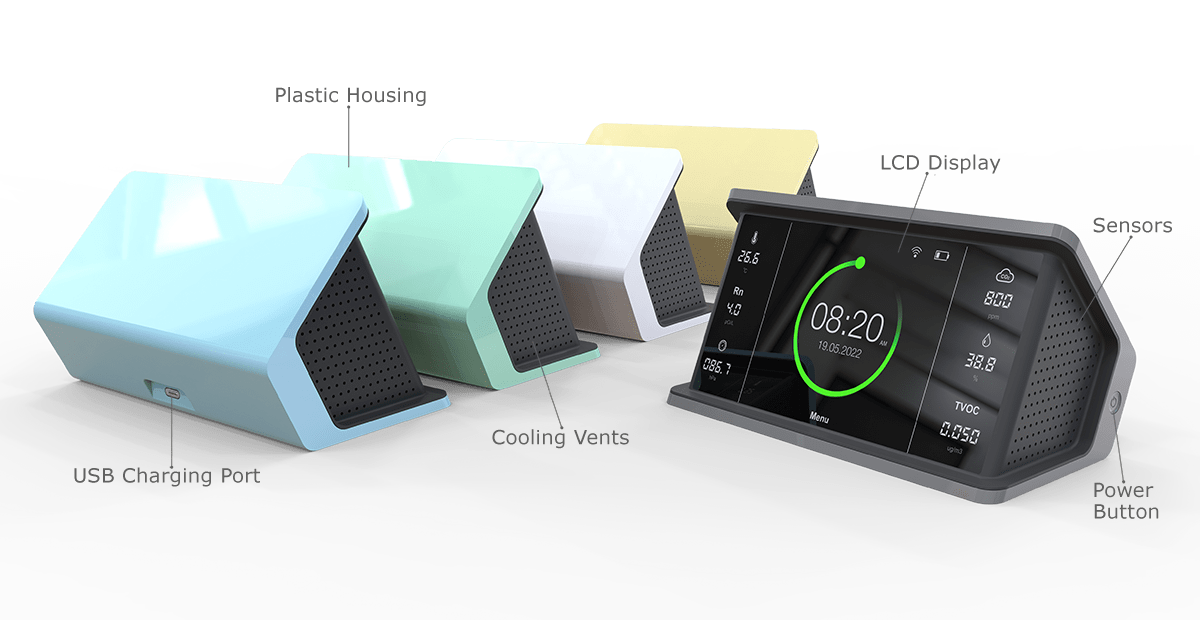

Home Air Quality Monitor

In one of our case studies, we developed a wearable device for a smart home system that tracks 7 air quality factors. Our industrial designers created a stylish and user-friendly device using 3D modelling and visualisation.

The eco-friendly device is made from recycled plastic and offers features like silent operation, touch-free controls, and smart home integration.

Fish Finder

We reviewed the industrial design and construction of the new generation echo sounders. Our designers took into account the customer's corporate identity and adapted the enclosure to the harsh conditions, including low temperatures, down to −30℃.

Also, we ensured full protection against dust and moisture according to the IP67 standard. This robust rubberised enclosure can withstand falling from 1.5 m.

Looking for a Reliable Industrial Design Company?

Finding a design partner is challenging

In the ever-changing business landscape, it is vital for companies to launch new products rapidly. However, ineffective and slow design processes can result in costly rework, usability issues, or manufacturing delays, and potentially lost business perspectives.

We transform your vision into reality

Industrial design services at Promwad cover the entire process of creating functional solutions with accelerated time to market. We transform user requirements into innovative products, controlling every design and development stage.

Look behind the scenes with us in the video, or get an overview of our expertise below.

3D modelling

As soon as we start developing the product concept, we make the first sketches and create 2D/3D images, based on the selected options with a variety of colour and texture solutions.

Mechanical design

Our mechanical engineers work with sheet metal bending, extrusion technology, MDF 3D printing, and use computer simulation for advanced engineering solutions.

We offer industrial design consulting to assist you in selecting optimal materials for the electronics enclosure needs, the client’s preferences and the chosen price range.

Rendering & visualisation

Visualisation (rendering) allows you to get a photorealistic image to show the colour and materials of a future product even before the prototyping and production launch.

We can check the device for assembly conformity, evaluate its look and convenience, as well as make the final decisions on the optimal materials and components.

Our experts can help with a choice of the best production site in Europe or South-East Asia, which will provide the required quality and acceptable business terms.

Results of Our Industrial Design Services

Technical design documents

A project file with industrial design details: costs, components, technologies, and specifications.

Drawings

for mass production

Detailed blueprints with dimensions, materials, and assembly instructions necessary for manufacturers.

Functional product

samples

Prototypes for evaluating a product's quality, functionality, and user experience before mass production begins.

Mass production support

Assistance in scaling your design for mass production and ongoing support during the production phase.

Why Clients Order Industrial Design from Our Company?

We are more than a software development company — we guide our clients' hardware products from concept to final batch delivery, ensuring they reach warehouses worldwide.

Analysis and prototyping

We analyse existing products, create prototypes, and develop custom enclosures.

Collaborative expertise

Our designers and production engineers work together to achieve optimal cost efficiency.

Eco-friendly approach

We prioritise sustainability, using biodegradable materials in our industrial design solutions.

What Our Clients Say

"At Kino-mo, we have developed the 3D Holo-Display, an innovative product which makes it possible to project 3-D images in the air. We turned to Promwad with the task of manufacturing new samples"

"Today, our IPTV STB is available at the market and competes on an equal footing with products by the world's leading manufacturers, such as Aminet and Motorola."

More of Our Completed Industrial Design Projects

How We Work With You

Drop us a line about your industrial product design project and get a quote!

We will contact you today or the next business day. All submitted information will be kept confidential.